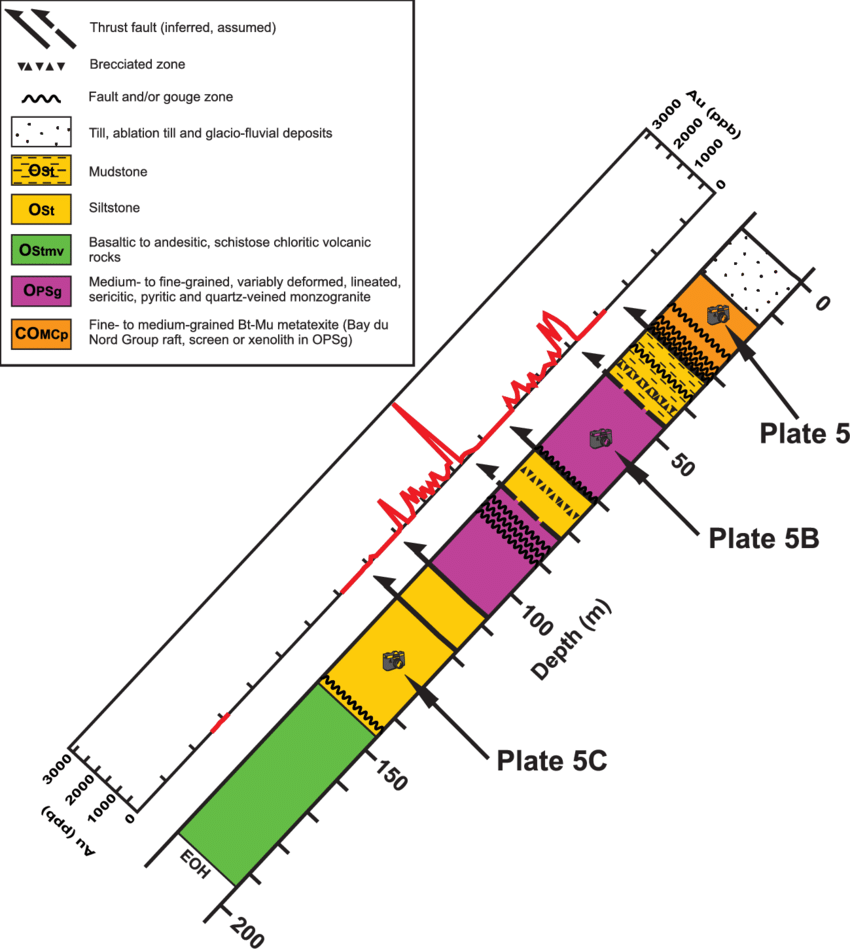

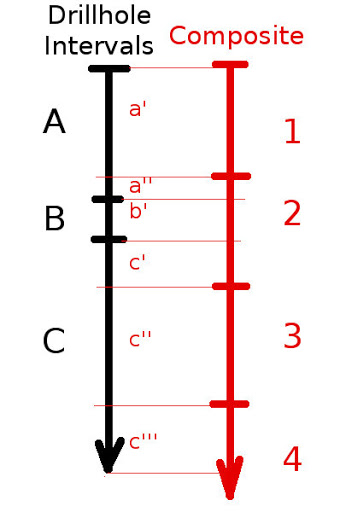

The original grade values (assays) in the database are usually averaged to pre-specified lengths: a procedure referred to as compositing. This is not strictly a requirement for resource estimation; however, the homogenization of the data scale or support and correction for incompletely sampled intervals motivates compositing in almost all cases. Most resource estimation software assumes the data are at a constant support.

Compositing also incorporates a certain amount of dilution into the raw data prior to estimation or simulation. The mining operation is expected to work at a certain level of selectivity that is larger than the scale of the raw assays. In the case of open pits, selectivity in the vertical dimension is generally fixed by the bench height. In the case of under- ground mines, selectivity is a function of the mining meth- od. The height of the lift or slice in a cut-and-fill or similar method determines the selectivity in the vertical direction. The composite length may be made equal to the bench or lift height to put data at the same vertical support as the mine selectivity.

The composite is typically calculated by a length-weighted average and may also be weighted by specific gravity and core recovery. Compositing can be done to obtain a representative value for ore body intersections, lithological or metallurgical composites, regular length down-the-hole composites, bench composites or section composites, high grade composites, or minimum length and grade composites.

Each of these types of composites are produced for different purposes and in different situations. Regular length or bench composites are most common in resource estimation. There are geostatistical models that can provide for mixtures of support sizes in the original data, but estimation software almost always assumes the data are of constant support.

Drill holes of different diameters are commonly used in the same deposit. There will also be partial composites at the end of drill holes or at hard geologic contacts. In practice, slight differences in support size will have little effect on the final resource estimate.

Consider an operation that has both reverse circulation (RC) and diamond drill holes (DDH) in its resource data- base. For a 1 m interval, a typical RC drill hole sample will represent close to 50 kg, considering that a 5.25-inch diameter hole is drilled. The corresponding HQ-size DDH, for the same 1 m length, will represent close to 28 kg. Although the two sample weights are quite different, the difference and its impact is negligible. This is because the sample is (a) usually composited, and (b) multiple composites are used to estimate blocks. The blocks may be as small as 5 × 5 × 5 m (for smaller, selective deposits), equivalent perhaps to 350 metric tons, and up to 25 × 25 × 15 m or larger blocks for massive depos- its, equivalent to almost 25,000 tons considering an in-situ bulk density of 2.65 t/m3. This will depend on the specific resource modeling case.

Further justification for compositing is that small scale assays may be highly variable, which can be mitigated by compositing. Compositing to an appropriate length will show less variability making the corresponding geostatistical analysis, including variography, more robust.

In particular, compositing has a dramatic affect on the nugget effect, that is, the completely random portion of the variability. The decrease in the nugget variance will be inversely proportional to the degree of compositing.

The composited dataset is important to the overall quality of the resource model. Several decisions must be made in practice, including whether or not to use composites; the most appropriate length; the compositing method used; whether to truncate the composites at geologic boundaries; how to handle missing intervals within the composite (with no assay information); and the minimum acceptable composite length.

If you want to see Drillhole compositing in action , and how to use it later in block modelling click the link below to join an online course that shows you exactly how to do this in one of the top mining packages Maptek Vulcan.

Also check out the first video of this course below you might find it useful